PORTSPECTIVE

Operational visibility

PortSpective offers terminals a true real-time view of their fleet productivity & performance with an essential insight into operator behaviour that will result in a safer working environment.

PortSpective monitors who is operating the equipment, tracks the equipment fleet in real-time providing location, status, performance and a full audit trail. Real-time telematic data ensures the highest equipment availability. Safety and security features promote a safer working environment and culture.

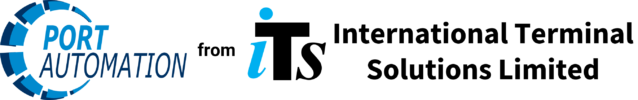

Real-time view

- View the terminal operation on a real-time map on any desktop, tablet or smartphone

- Zoom out for the entire operation

- Zoom in to view areas of interest

- View running, stopped and out-of-service equipment

- View on a web browser on any compatible device

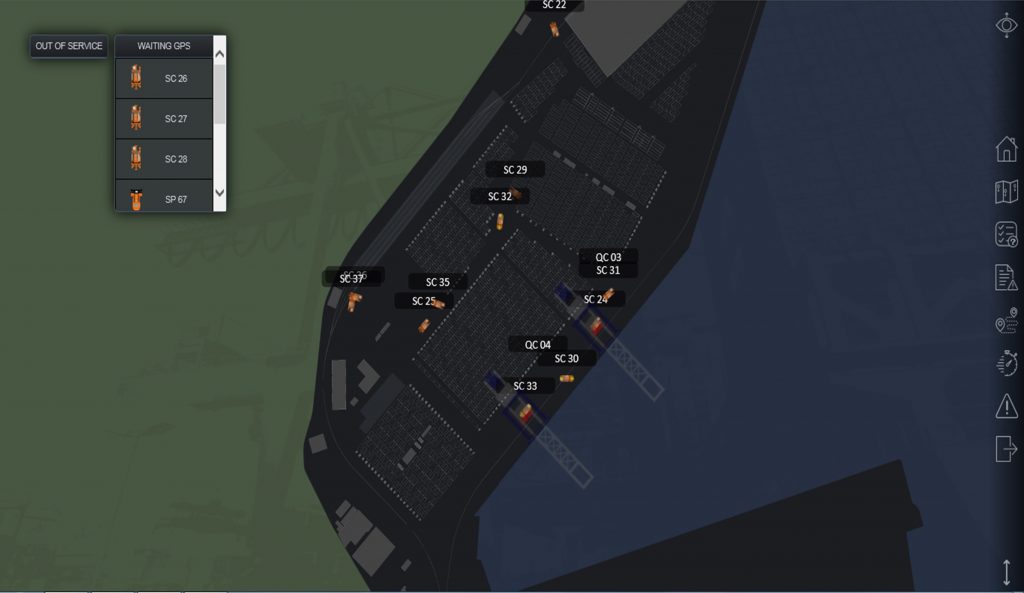

Zoom

- Zoom to view areas of interest or follow a specific piece of equipment

- Show loaded... or unloaded status

Status Overview

- View the equipment operational status as an overview

- Fuel level

- Running hours

- Key metrics and faults

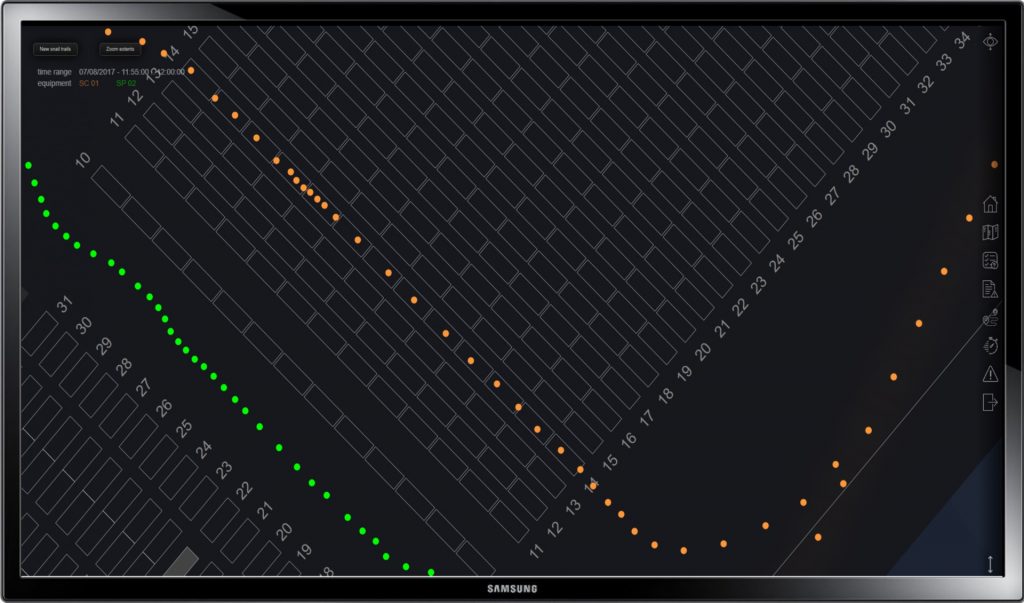

Snail Trail

Snails leave trails, so does your equipment when equipped with PortSpective.

You'll have the ability to view historical equipment trails.

The map used for the Snail Trails is the same as the Live View. If an individual dot is selected a pop-up will appear to show the attributes.

Live Performance Statistics

- Moves per hour

- Idle time

- Stability alarms

Equipment pop-up and fault alarms

Map views, status views and historic analysis screens have a range of warnings and equipment status information.

Operational Safety

All container terminal operators recognise the benefits of improving operational welfare for their employees and on-site contractors.

It is without doubt that many have also adopted a proactive approach to operational safety, recognising not only the benefits to the welfare of the workers through a safer working environment, but also the additional benefits this will bring to the day to day operation by minimising disruptions and providing a more stable and predictable operating environment.

However, how do you achieve the implementation of best practice in a busy container terminal where the operation is spread over a wide area? How do you make sure that it is the trained operator that is driving, and just as importantly how do you measure the effectiveness of your accident prevention efforts? Waiting for the next accident is not an option.

Equipment Stability

Several factors contribute to equipment instability such as yard layout, equipment design, and the effect of individual operators.

PortSpective allows instant visibility of these trends and provides differentiation between these various contributing factors.

Stability Trails

- Identify areas of the yard with stability issues

- Historically analyse events

- Identify contributing factors - speed, load too high, operational practices

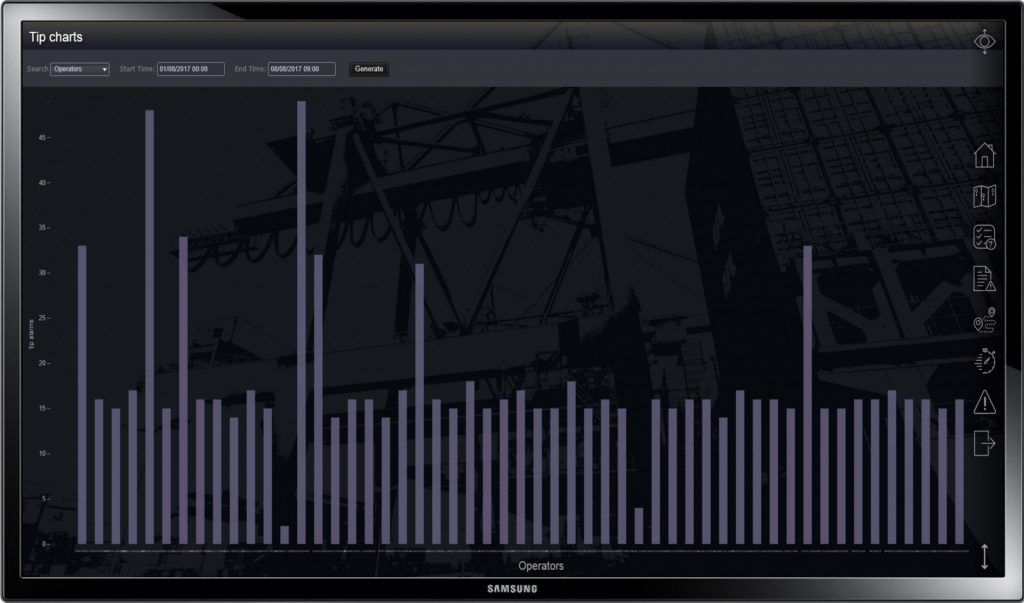

Stability alarm statistics

- Compare equipment stability

- Compare operator behaviour

The next step

Contact us to discover how PortSpective can be tailored for your terminal.